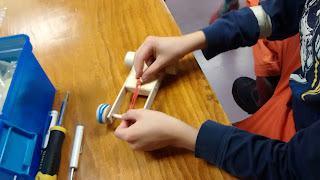

The kids had to assemble all the parts, consisting largely of some screws, washers, rubber bands, and prepared wooden components; and then see how well they could get the little things to go. They could experiment with front wheel versus rear wheel drive, different levels of tension on the rubber band drive, and various methods for creating traction on a smooth table. We had a track set up on another table with yard stick rails (special thanks to J&L Hardware!) so that the kids could race their cars to see which configuration would go fastest and farthest. The library staff at the Fairfax Community Library has been very accommodating. Let's see how they do with next month's project...

What might not be totally apparent is that Ralph created these kits and fabricated all the pieces himself. The wheels were all hand-turned on his machine shop tools and he pre-drilled, and test assembled every single one of them (about 15 in all). He even waxed the holes for the screws and axles to make everything go smoothly. This pales in comparison to the wire coils he pre-wound for the earlier simple motor project (and the winding machine he scratch built to assist) but I'm sure it was a significant time commitment all the same. I keep telling him that I want him to teach me how to use the machine shop tools. Now if I can just get some regular time to get over to his place to learn!

73 de KB1VNA

Eric

Ralph is truly amazing, the library is lucky to have a partnership with him. Hooray for hands-on learning!

ReplyDelete